In an innovative breakthrough at Sweden’s Chalmers University of Technology, researchers have demonstrated that sodium-ion batteries are not only resource-efficient but also have a comparable climate impact to lithium-ion batteries. This discovery is crucial in addressing the rising concern over the depletion of critical materials like lithium and cobalt, essential for the burgeoning electric vehicle industry.

The study, led by Rickard Arvidsson and published in the Journal of Industrial Ecology, highlights the limitations in the natural availability of lithium and cobalt. These materials are concentrated in a few global locations, posing significant supply risks. In contrast, sodium-ion batteries, made from abundant materials, offer a sustainable alternative with a considerably lower impact on mineral resource scarcity.

Arvidsson’s team conducted a comprehensive life cycle assessment of sodium-ion batteries, examining their environmental and resource impact from raw material extraction to manufacturing. The results revealed that sodium-ion batteries produce between 60 to just over 100 kilograms of carbon dioxide equivalents per kilowatt-hour of theoretical electricity storage capacity. This figure is promisingly lower than previous estimates for this type of battery, showcasing its potential as a sustainable technology.

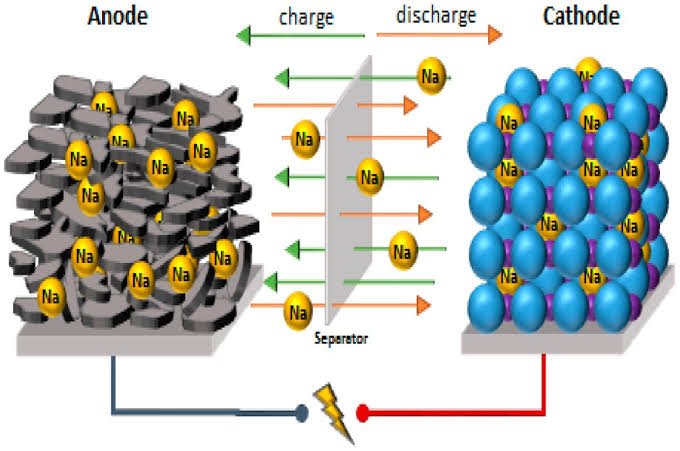

Sodium-ion batteries, already expected to be utilized for stationary energy storage in electricity grids, show great promise for future use in electric vehicles. The technology’s major advantage lies in its use of widely available materials. For instance, one electrode – the cathode – utilizes sodium ions as a charge carrier, while the other – the anode – is made from hard carbon, potentially sourced from biomass from the forest industry. This approach could significantly reduce geopolitical risks and dependencies on specific regions for both battery manufacturers and countries.

The study presents a prospective life cycle assessment of two different sodium-ion battery cells, calculating the environmental and resource impact from raw material extraction to the manufacture of a battery cell. The batteries primarily use abundant raw materials: the anode comprises hard carbon from bio-based lignin or fossil raw materials, and the cathode is made of “Prussian white” (containing sodium, iron, carbon, and nitrogen). The production process is modeled on a future, large-scale production analogous to current lithium-ion battery production in gigafactories.

This research also tested various scenarios using different electricity mixes and allocation methods for resource and emission distribution. The outcomes affirm that the climate and resource impact of sodium-ion batteries could be distributed based on coproducts’ mass or allocated entirely to the main product (the sodium-ion battery and its components and materials).

This groundbreaking study at Chalmers University offers a glimpse into the future of battery technology. It underscores the need for sustainable solutions in energy storage, vital for the expansion of renewable energy sources like wind and solar power. As the demand for electric vehicles and sustainable energy solutions grows, sodium-ion batteries emerge as a promising, resource-efficient alternative to the current lithium-ion technology, potentially reshaping the landscape of battery production and usage globally.